Infill Panel Wall Insulated Can Be Fun For Everyone

Table of ContentsSome Ideas on Infill Panel Wall Insulated You Should KnowThe 9-Second Trick For Glazing Infill PanelsHow Glass Infill Panels can Save You Time, Stress, and Money.The smart Trick of Infill Panel Wall Insulated That Nobody is Talking About

If contemporary appearance of standing joint steel roofing is not exactly ideal for your house, then you can choose steel roof shingles roof covering that works well for historic buildings, as well as gives the standard want to your roof covering.Whether you require Glazing Infill Panels, Spandrel Panels, Shadow Boxes, Soffits, Copings, Backpans or Flashings, Embury Firm will deliver promptly and on budget. Let our team help and overview you through all of you metal panel demands. Our State-of-the-art Facilities permits us to function effortlessly with any type of kind of material and also get you what you require.

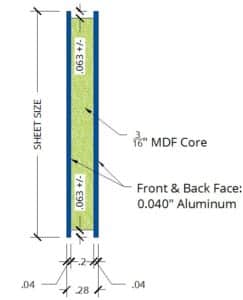

The panels are offered from.016 to 3/16 (.1875) of an inch, utilizing Light weight aluminum, Stainless Steel, Galvanized or ACM. Whatever the thickness, product or surface Emburite Panels will certainly address the requirement.

The Drape Wall surface style describes mid-20th Century structures that use a premade exterior wall surface sheathing system hung to their structures - lightweight in fill panels. Using such modern technology dates back to the 1918 Hallidie Structure in San Francisco, which is attributed as the very first structure to make use of an all glass exterior wall surface system.

The first major instance of the style was the Equitable Cost Savings & Finance Structure in Rose city, Oregon performed by engineer Pietro Belluschi in 1948. As the world's initial fully confined cool structure, this streamlined 12-story framework promptly established the pattern for lots of post-WWII high-rises and also little scale office structures. The curtain wall surface system is included a repeated grid of vertical extruded aluminum mullions as well as straight rails.

Some Of Mapes Metal Panels

These spandrel panels can can be found in a range of materials. Early spandrel panels were constructed from heat-strengthened nontransparent glass merged with colored ceramic. The Pittsburg Plate Glass Company manufactured the glass panels under the brand name "Spandrelite," as well as used eight standard shades. The Libbey-Owens-Ford Company marketed sixteen colors choices under the "Vitrolux" brand name.

Thought about ideal for essentially any kind of size commercial, government or institutional structure, the Curtain Wall surface design came to be extensive by the early 1950s. Lots of post-WWII structures of differing styles additionally integrated drape wall surface systems right into some exteriors but are not thought about Drape Wall surface style unless the bulk of the visible facades are so built (infill panels for windows).

Curtain wall and also shop glazing systems are generally a thin, non-structural outer faade component of a structure that can span several floors or be integrated into a punched opening. Glazing systems function mostly as air and water vapor barriers, standing up to air or water seepage as well as accommodate building and also system motion caused by wind, thermal, as well as seismic forces.

As such, light-weight materials can be used in their growth. Industrial glazing systems are generally created of aluminum-framed walls with glass, metal panels, louvers, operable home windows or vents, or stone veneer infills. Building envelope experts will usually suggest designers on curtain wall surface and also shop requirements for constructing movement, thermal development as well as tightening, water diversion, and thermal performance.

Nontransparent glazing, steel panels, MCM (steel composite products) panels, or shielded laminated panels are commonly used as spandrel infill. When insulation is used inboard of the spandrel infill, an air room is regularly introduced to stop thermal damage to the spandrel infill. Unfortunately, navigate to this site the air area can give a chance for condensation to create on the indoor face of the spandrel infill.

The smart Trick of Mesh Infill Panels That Nobody is Discussing

Must badly developed spandrel conditions be left neglected, condensation can cause moisture or aesthetic damages to the spandrel panel and/or indoor surface areas. When condensation types at the spandrel infill of a glazing system, numerous sorts of damages can happen, and also the results of condensation can be far-reaching. In enhancement to dampness damage and microbial growth, condensation growth on spandrel infill can also have a negative effect.

One method to postpone the formation of condensation on the glazing system spandrel infill is to utilize the building HVAC system. By boosting air movement near these areas, more warm will certainly be moved to the setting up and also increase interior surface temperatures. One more method to make use of the HEATING AND COOLING system is by minimizing the inside relative moisture set points with regard to outdoors temperature.

Our Infill Panels For Windows Diaries

In addition to integrating recovery methodology, means to decrease condensation possibility throughout layout include: Typically curtain wall surface systems have anonymous greater resistance to condensation than storefront systems. Using drape wall surface is one way to lessen, or postpone the beginning of condensation development. At Pie, we provide 2-D thermal modeling (THERM) to assist our customers with the layout of spandrel areas.

By knowing surface temperatures, Pie has the ability to identify under which problems condensation will certainly happen, along with identify transition factors at which condensation will not establish, making it less complicated to anticipate as well as remediate (mapes architectural panels). On top of that, numerous configurations can be designed to make the most of interior surface temperatures. Installing back pans into the spandrel infill glazing pocket, which are vented to the exterior with insulation outboard of the frying pan, promotes boosted interior surface area temperature levels with the included advantage of click resources reducing warm transfer through the spandrel infill.